Ethanol: clean fuel, stronger economy – insights with S&T experts

Posted by Kaitlin Brothers

An ethanol production plant in South Dakota.

Ethanol has become a major part of America’s energy landscape.

It was first used in cars, and is now mixed into most gasoline sold in the U.S. This rise has been driven by environmental concerns, energy security and advances in technology. Today, ethanol helps reduce carbon emissions while creating jobs and supporting rural economies.

Dr. Greg Gelles, professor emeritus of economics, and Dr. Joseph Smith, professor in the Linda and Bipin Doshi Department of Chemical and Biochemical Engineering, are experts in the economics, environmental impact and future ethanol production in America.

Both Gelles and Smith responded to the following questions.

Can you give a brief history of ethanol production in the United States?

Ethanol was first used as an automotive fuel in the 1920s and 30s. In early 2000, ethanol demand grew significantly due to energy security concerns and the U.S.’s increased dependence on imported oil. Environmental concerns related to Methyl tert-butyl ethers (MTBEs), used as fuel oxygenate, created additional demand.

In 2007, President George W. Bush signed the Energy Independence and Security Act with the goal of increasing renewable fuel production to 36 billion gallons by 2022.

What is the present volume of ethanol production in the United States?

U.S. ethanol production increased every year since 2000 with 2024 production reaching a record 16 billion gallons for an annualized growth rate of less than 8% per year. In addition, 2024 ethanol exports were 1.9 billion gallons with Canada importing nearly 50% of our exports. Iowa ranks as the largest state producer at 4.9 billion gallons. Most cars today use gasoline blended with ethanol (10% ethanol and 90% gasoline) referred to as E10. Some vehicles are tuned to use E85 (85% ethanol and 15% gasoline).

Is the increase in ethanol production in the U.S. associated with a corresponding increase in the number of operating ethanol plants?

The number of U.S. ethanol plants reached a maximum in 2011, when the corn farm subsidy was removed and decreased until 2015. The number has remained steady since then. During our visit to POET’s ethanol plant in Laddonia, Missouri, in 2013, they produced about 50 million gallons while in 2025 they produced over 80 million gallons.

In 2013, they produced about 2.7 gallons of ethanol per bushel of corn while today they produce 2.97 gallons per bushel, and they expect to produce less than three gallons per bushel next year. Significant advancements in agricultural science related to new hybrid corn and advanced farming techniques have also increased corn production from 150 bushels per acre to over 190 bushels per acre today.

To what extent is the ethanol market sustained by federal subsidies?

Steve Murphy, POET’s Laddonia plant manager, said that direct farm subsidies for U.S. ethanol blenders ended in 2011, although some states (including Missouri) still have a $0.05 per gallon incentive for blends less than 10% (for example, E15) but this “blenders credit” is paid to refiners, not ethanol producers. Steve also said there is a federal tax credit of 45 cents per gallon of ethanol when blended with gasoline.

Is corn the main raw material used worldwide in making ethanol?

Today, over 80% of the world’s ethanol production occurs in the U.S. and Brazil. While most of the U.S. ethanol is derived from corn, Brazil produces most of their ethanol from sugar cane. Recently, Brazil has begun growing more corn and constructed new corn ethanol plants similar to the U.S. plants.

As a biofuel that adds no net CO2 to the atmosphere, why is there an effort to capture the CO2? Does that add to the cost?

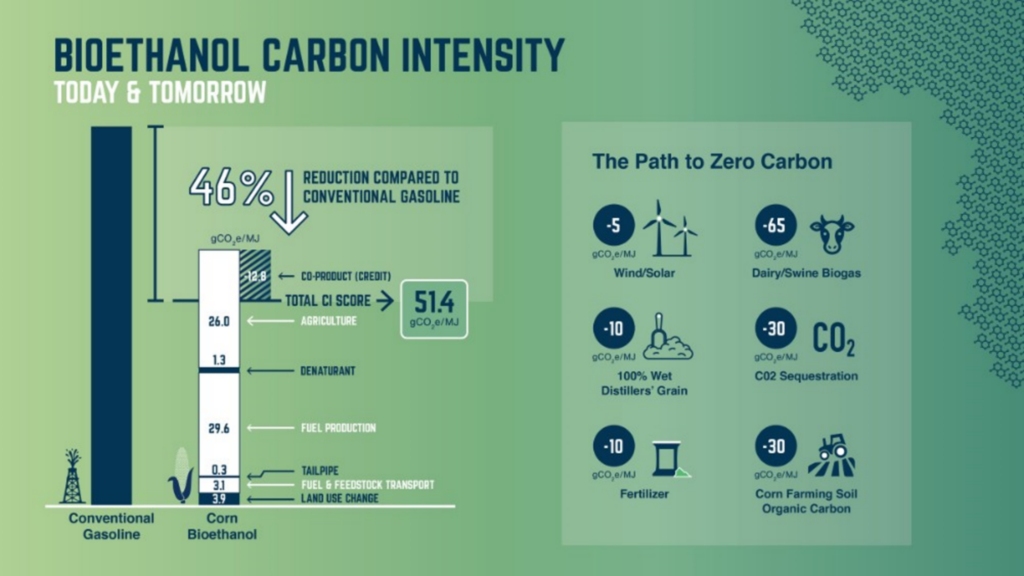

To reduce transportation’s carbon footprint, the government is focused on lowering the carbon intensity (CI) of transportation. Support for electric vehicles using renewable energy to generate required electricity and increasing the blend level for ethanol in gasoline are other ways being used to reduce transportation’s CI.

Mandates to use the Department of Energy’s GREET software to estimate the CI for transportation is now required for all government grants and loan guarantees. A recent university study concluded that ethanol has a CI score of 41.7% gram-equivalant-CO2 per million joules. So, using E85 would reduce the transportation carbon footprint in the U.S. with additional savings possible.

In modern day ethanol plants, what products are made other than ethanol?

During our plant visits to Laddonia, we witnessed the hybridization of POET’s ethanol production. Today, they produce animal feed (distillers’ grain), as well as corn oil, dry ice and electricity (used to power the plant with excess sold back to their provider). Producing multiple products has increased their economic performance.

Is there a future for cellulosic ethanol?

Cellulosic ethanol is made from non-food plant materials (such as corn cobs, grass or wood waste). The challenge in producing ethanol from cellulose is that the starch content is much lower, thus ethanol production is lower and more expensive. Currently, there are cellulosic ethanol plants in Brazil that represent a very small portion of the country’s total ethanol production.

Photo Tom Wagner/Missouri S&T.

Brazil has said their plan is to build 20 more plants by 2027. Over the years, the U.S. government has funded several attempts to develop a profitable cellulosic ethanol plant. POET’s Project Liberty resulted in an operating cellulosic ethanol plant as part of an operating corn ethanol plant. This plant has since been decommissioned due to lower economic performance. An article in the March 2025 edition of Ethanol Producer Magazine announced “New Energy Blue” will build a cellulosic ethanol plant in Iowa using corn stover as its feedstock and projected to provide 20 million gallons of ethanol per year.

The idea of using low quality feedstock to produce biofuel is one of those projects that Gelles claims will never happen. Smith is more optimistic and believes, like other engineering challenges, society will eventually figure out how to make ethanol from cellulose economically.

Has the growth in the ethanol industry had a positive economic impact on rural America?

The local economic impact of POET’s Ladonnia plant is clear. This plant has created 50 high paying jobs and increased corn demand from local farmers. The ethanol market has had a positive economic impact on the total U.S. economy as well.

In 2024, the Renewable Fuels Association concluded that in 2023 about 72,400 U.S. jobs were directly associated with the ethanol industry with an additional 322,000 indirect jobs supported by the industry. They reported that the industry generated $32.5 billion in household income and contributed just over $54.2 billion to the nation’s gross domestic product.

About Missouri S&T

Missouri University of Science and Technology (Missouri S&T) is a STEM-focused research university of over 7,000 students located in Rolla, Missouri. Part of the four-campus University of Missouri System, Missouri S&T offers over 100 degrees in 40 areas of study and is among the nation’s top public universities for salary impact, according to the Wall Street Journal. For more information about Missouri S&T, visit www.mst.edu.

Leave a Reply